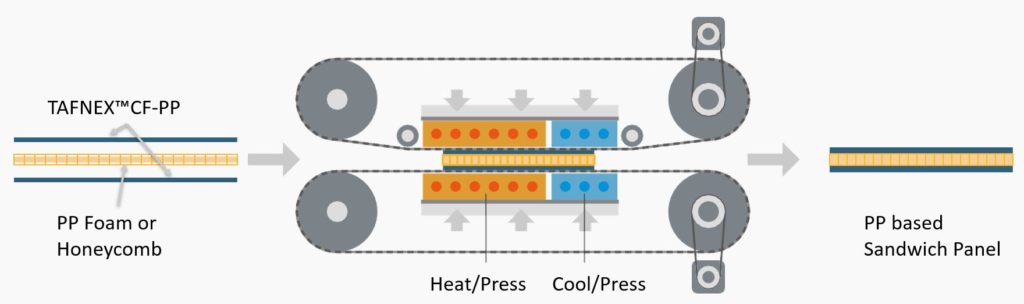

- TAFNEX™ can be combined with PP-Foam, PP-Honeycomb or other PP compatible cores materials

- The mechanical and forming properties can be freely adjusted by the lay-up and the sandwich core

- It is possible to functionalize the sandwich panel afterwards (e.g. injection molding, thermoforming, etc.)

Processing methods of thermoplastic sandwich panels

Continuous production for high volume applications by using a doublebelt press:

Discontinuous production for small quantities by using a stamping process:

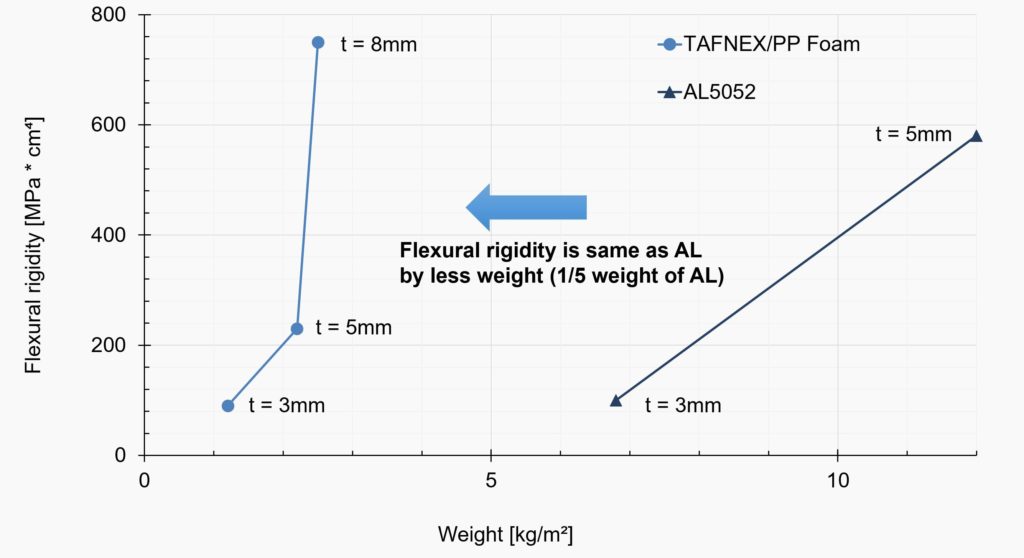

Combination of TAFNEX™ and PP-Foam compared to aluminium panel

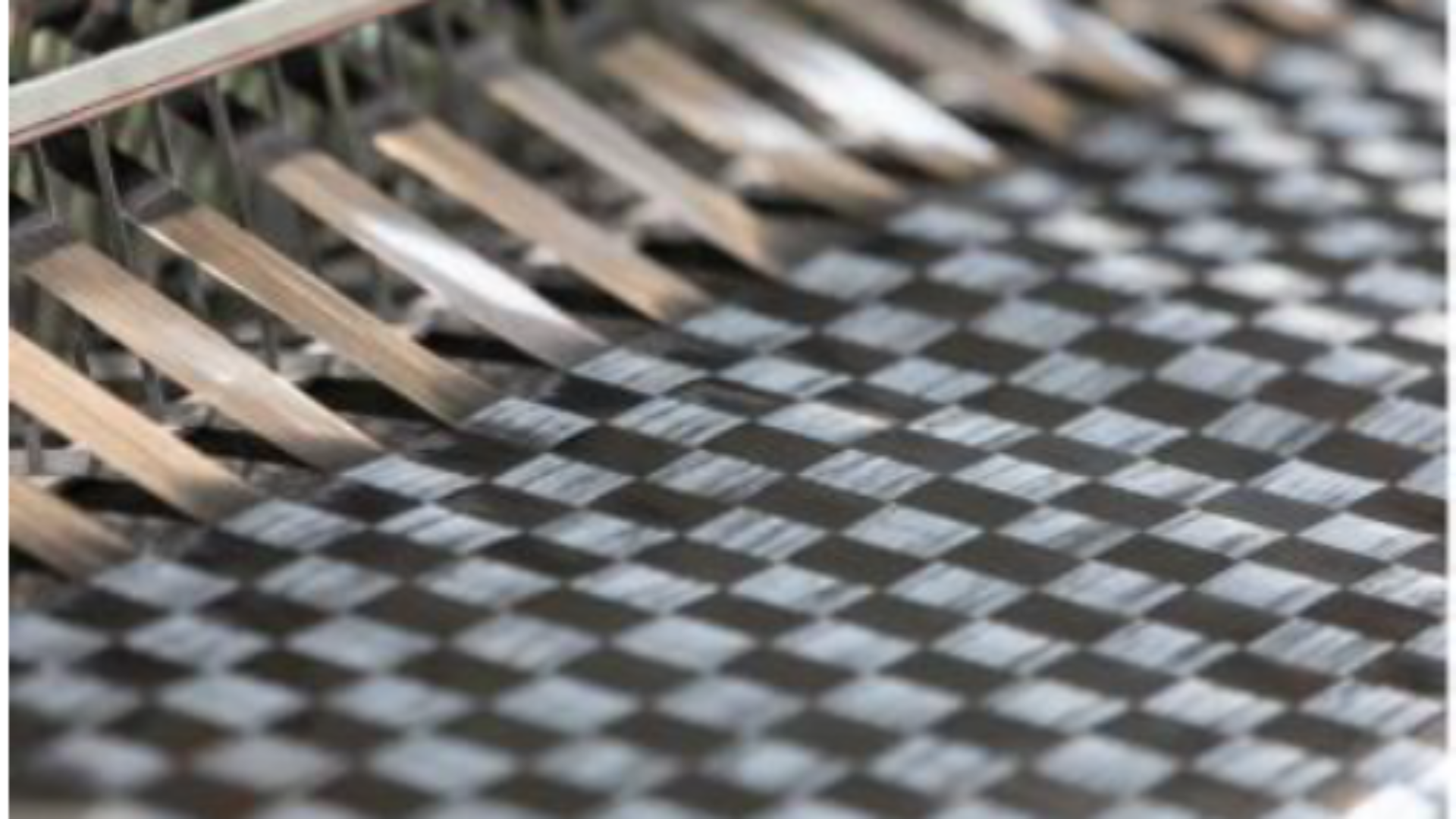

Related Cases

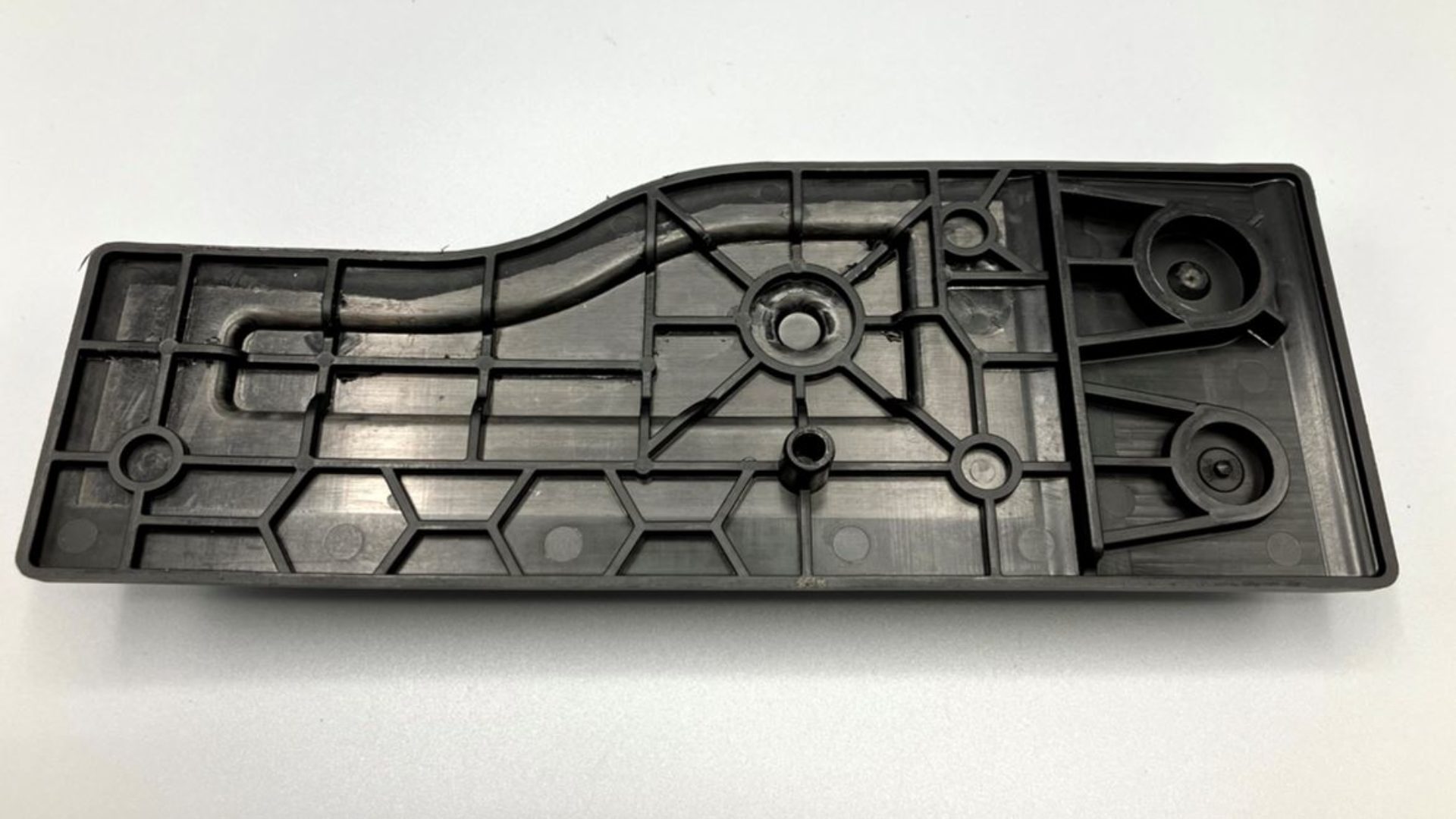

Automotive Interior Demonstrator

Process Development for an interior automotive part in cooperation with HRC Group

Mold temperature study

Processing Study of mold temperature and the relation to mechanical properties