Concept study of a polylefine based seat design

Re-design of a virtual seat demonstrator using TAFNEX™ CF-PP UD and CF-PP LFT material and substituting metal parts

Mitsui Chemicals and ARRK as part of the Mitsui Chemicals Group work together on the development, manufacture and elaboration of applications of these materials for the automotive industry. With extensive knowledge on the starting materials and long experience in the product development process, the two companies pool their expertise for the optimum use of fibre-reinforced thermoplastics in vehicles and other parts.

...

+ Material development

+ Material supply

Customized solution with different materials possible on request

...

+ Design

+ Engineering

+ Material testing

+ Component testing

+ Tooling

+ Prototyping

...

+ Component simulation

+ System simulation

+ Optimisation

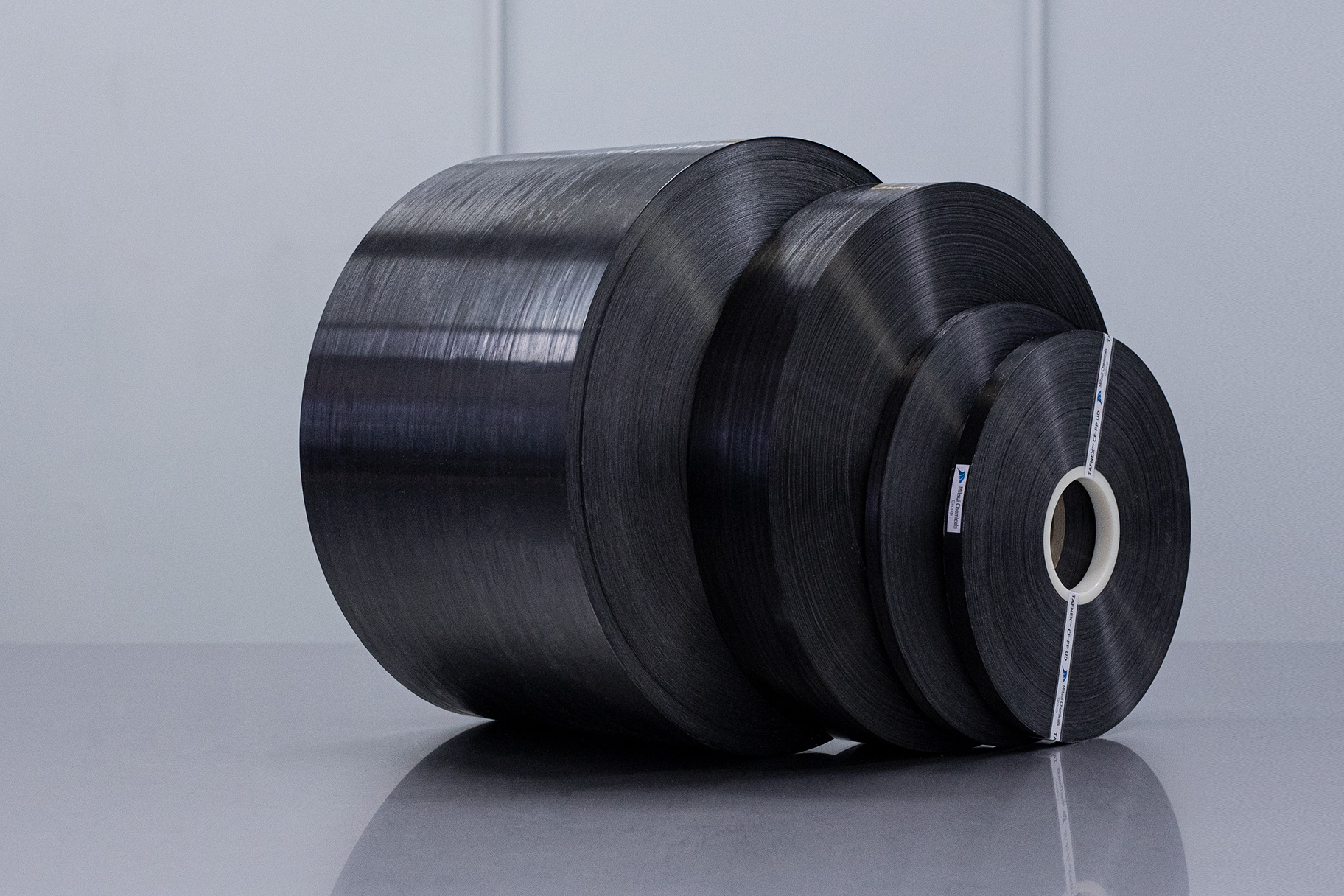

Sampling material

Sample production via partner network

To support projects in every development step, we started over the past years to create a partner network. For example, we are able to support you with hybrid products combining TAFNEX with other materials. Also we can connect you with machine oder part supplier.

Method development and design strategy

Simulation (crash & crushing, strength, fatigue, NVH, acoustics, multi-body, CFD)

Lay-up, layer optimization and draping simulation

Evaluation of results and component optimization

ANSA, HyperMesh, MSC Patran/Nastran, Abaqus, Ansys, Pamcrash, LS-Dyna, Radioss/Optistruct, Theseus-FE

Re-design of a virtual seat demonstrator using TAFNEX™ CF-PP UD and CF-PP LFT material and substituting metal parts

JEC World 2019 in Paris, France, Mitsui Chemicals unveiled the “hour´s Pod” concept car

Simulation-based product optimization with modified delamination prediction in crash case. Cooperation project between Mitsui and ARRK Engineering

Mitsui Chemicals and ARRK as part of the Mitsui Chemicals Group work together on the development, manufacture and elaboration of applications of these materials for the automotive industry. With extensive knowledge on the starting materials and long experience in the product development process, the two companies pool their expertise for the optimum use of fibre-reinforced thermoplastics in vehicles and other parts.

In the R&D Division, we will expand ways to pursue customer-driven innovation to achieve growth in targeted business domains and create new businesses and products. With TAFNEX™ CF-PP UD we are supporting the ARRK Group in the composite field and starting the service solution chain with our material expertise.

ARRK Engineering offers its reowned customers an end-to-end engineering support with a comprehensive range of services. With our expertise in Electronics & Software, CAE & Simulation, Material, Acoustics, Composite, Car Body, Powertrain, Chassis, Interior & Exterior, Optical Systems, Passive Safety and Thermal Management we are developing as a long-time strategic partner products for our customers.

The cornerstone of ARRK's success in delivering excellence over the years has been its prototyping service. Our team has amassed a wealth of knowledge and experience, and utilised some of the latest prototyping technologies around today. With prototyping centres strategically located across Europe, we are ideally placed to provide a comprehensive service that is local to you.

At ARRK we’re here to support you with a comprehensive Tooling capability. Whatever your needs we can assist you with Rapid, Prototype & Pre-Series Tooling, Low Volume Tooling or Production Tooling, along with a range of Tooling Support Services. From tool maintenance, refurbishment, modification or calibration we’ve got it covered for you.

ARRK can support clients with a wide variety of low volume production solutions for plastics, metals, and composites components.