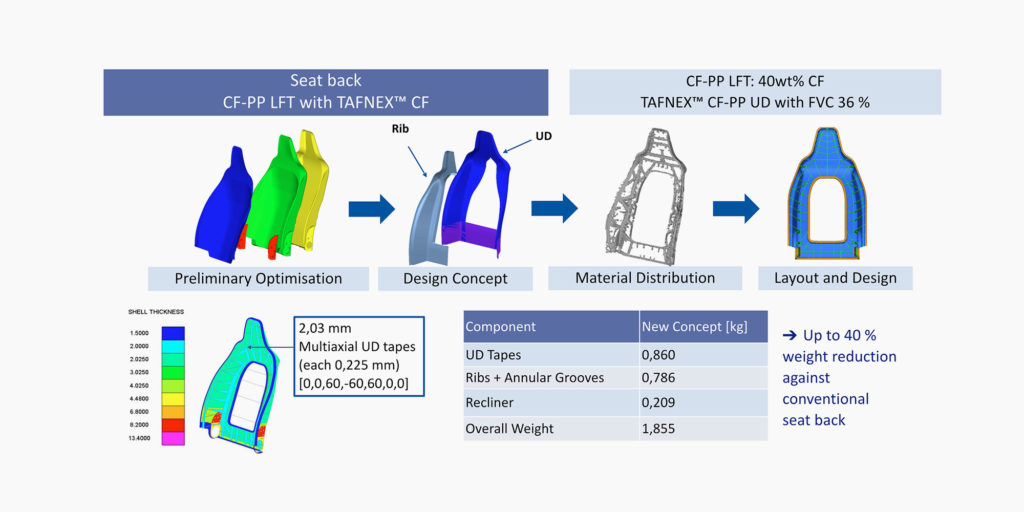

Re-design of a virtual seat demonstrator using TAFNEX™ CF-PP UD and CF-PP LFT material for substituting metal parts. Potential weight reduction up to 40% against conventional seat back.

Seat development steps

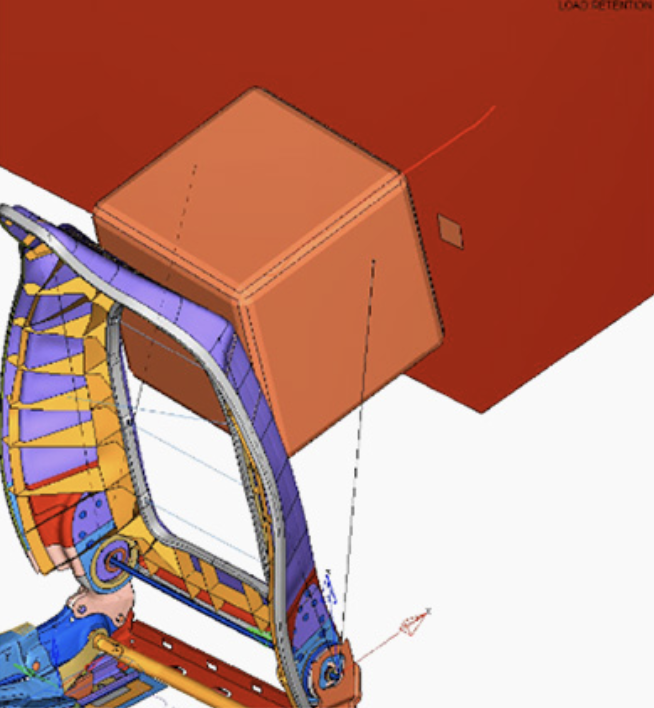

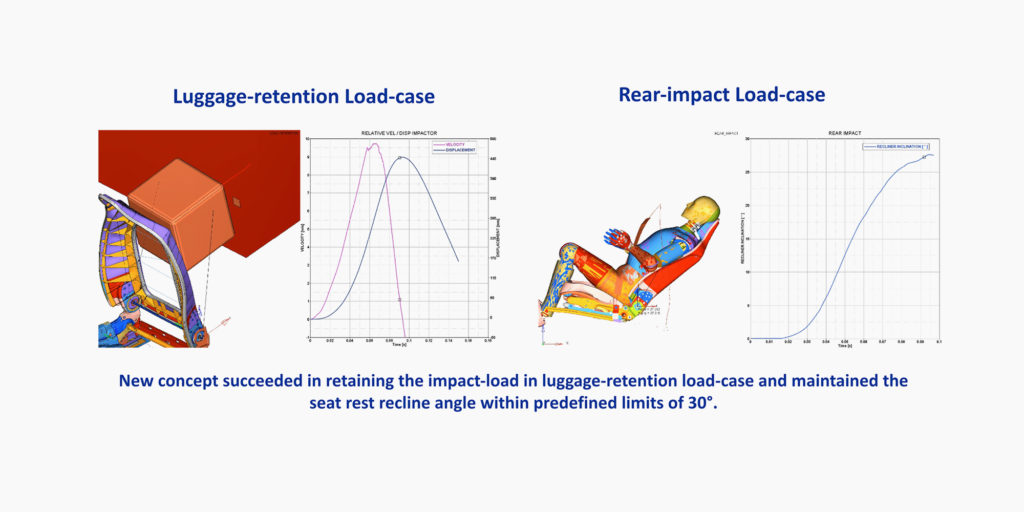

Result of Concept study

Related Cases

Recycling study of TAFNEX™

Investigation of three TAFNEX™ waste streams and mechanical testing of the recycling grades

Local reinforcement of a tailgate

Mechanical properties increased by adding TAFNEX™ CF-PP UD in the injection molding process

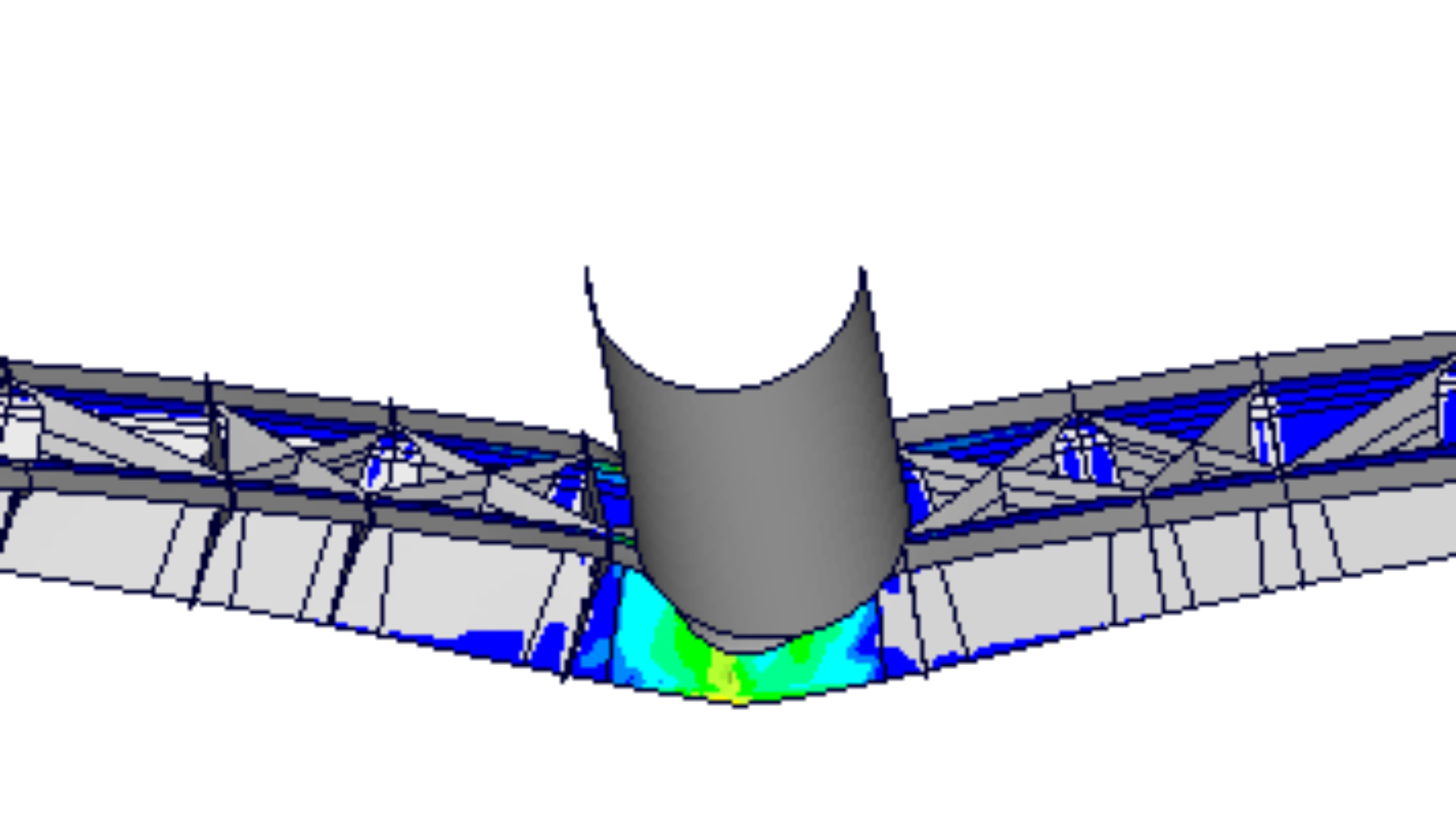

Simulation of a front bumper beam

Simulation-based product optimization with modified delamination prediction in crash case. Cooperation project between Mitsui and ARRK Engineering