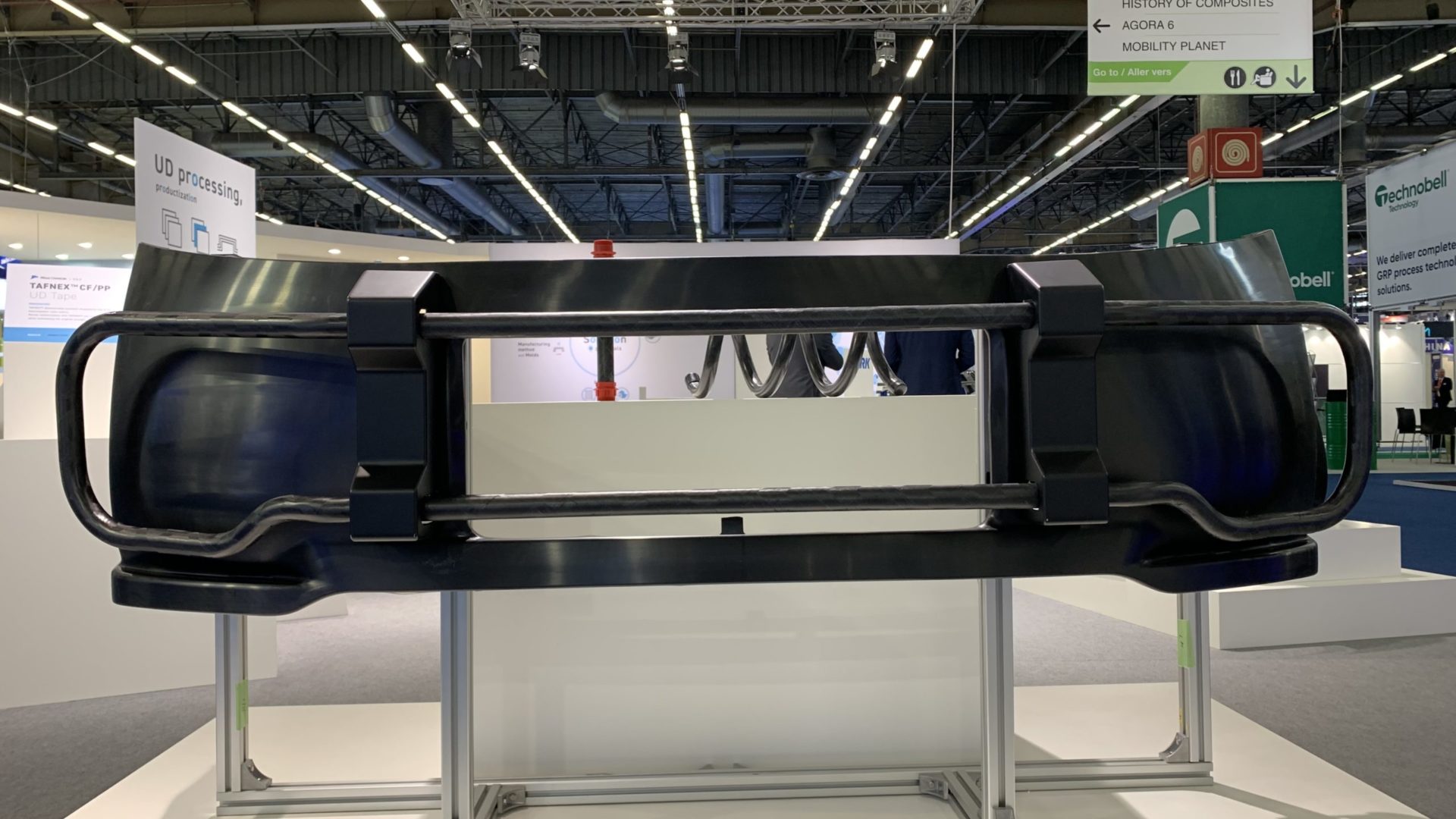

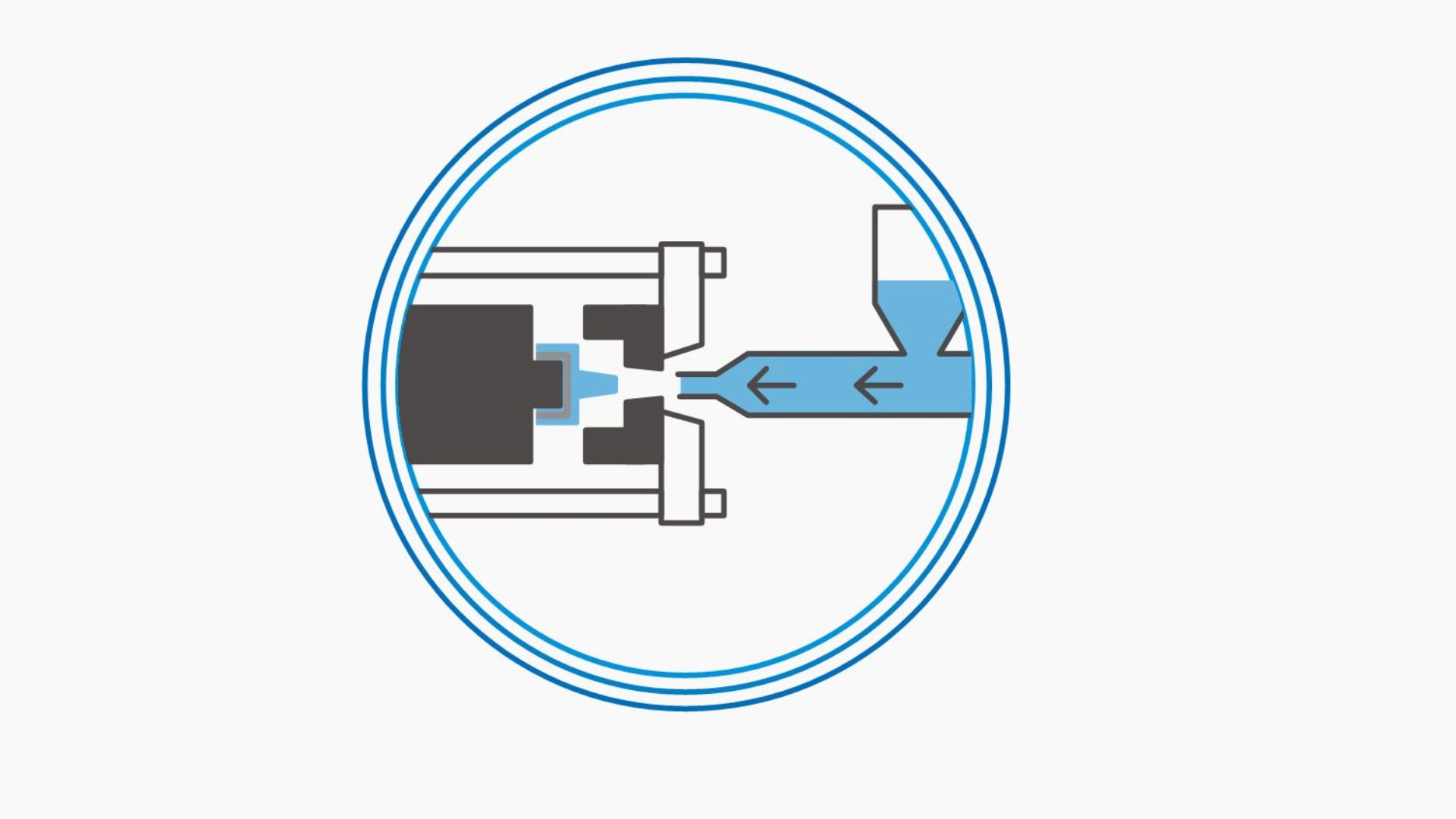

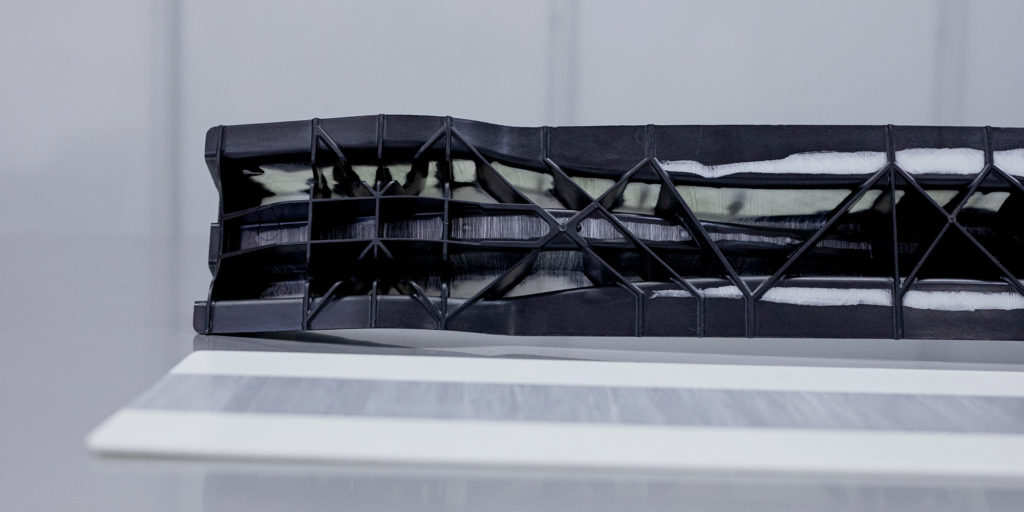

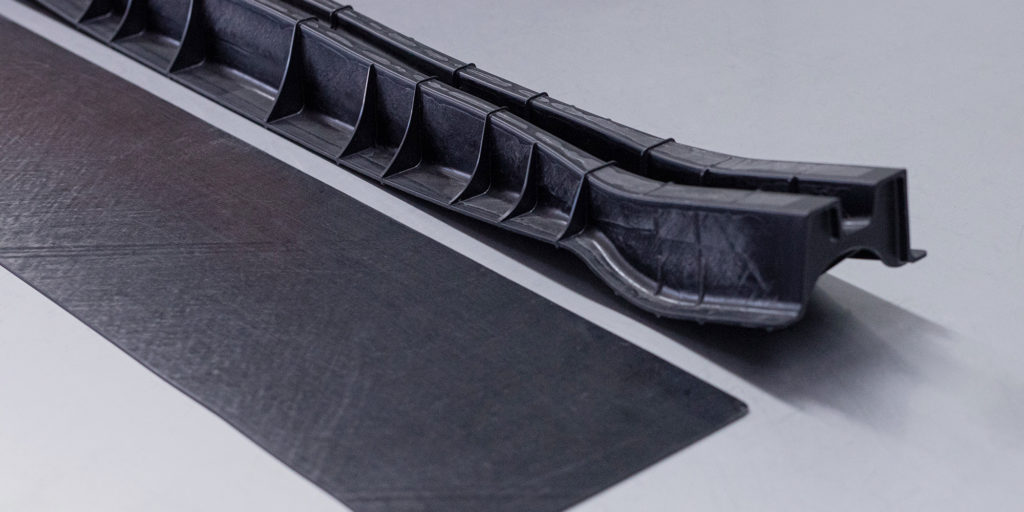

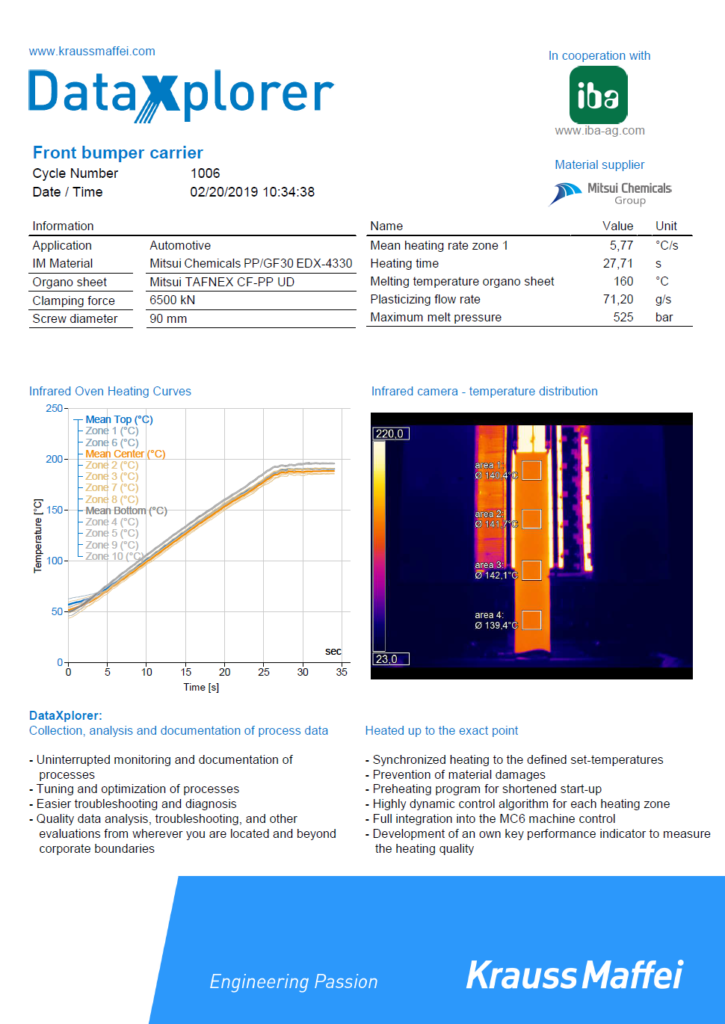

The front bumper beam was made with the FiberForm technology from Krauss Maffei Group. The process is a combination of sheet forming and back injection molding. The front bumper beam geometry was provided by Krauss Maffei based on a previous public funded project. In this individual study, composite and compound material are supplied by Mitsui Chemicals. The composite sheet is also customized for the specific loadcase by using TAFNEX™ UD layers and was produced by Van Wees | UD and CrossPly Technology.

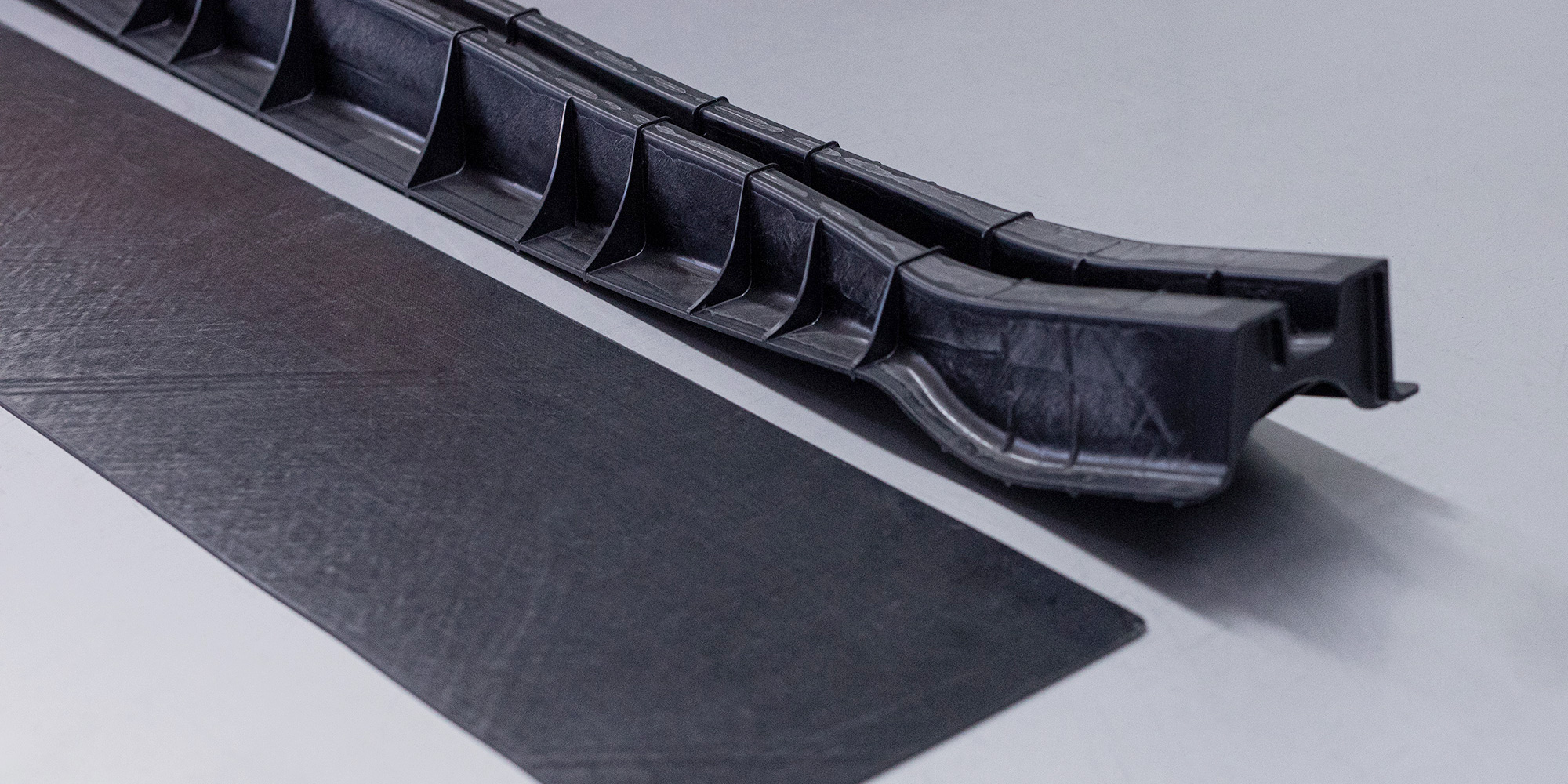

Two composite sheet variants have been used:

+ Full CF-PP sheet made of TAFNEX™

+ Hybrid sheet made of TAFNEX™ and GF-PP UD tapes

By using this combination of different thermoplastic processes and materials it is possible to substitute the metal parts. By integrating more functions in one part it is possible to reduce process cost and cycle time.

Sheet production

Process Video: Sheet forming and back injection molding

Related Cases

Local reinforcement of a front bumper fascia

Mechanical properties increased by adding TAFNEX™ CF-PP UD afterwards

Local reinforcement of organosheets

Local reinforcement of organosheets with TAFNEX™ CF-PP UD Tape improves the stiffness and the mechanical properties.