TAFNEX™ Drone solutions

Lightweight, efficiency & safety for UAVs

TAFNEX™ is a cutting-edge thermoplastic carbon fiber material that is both easily recyclable and lightweight.

Its outstanding versatility in processing allows you to manufacture a wide variety of drone components, each perfectly

tailored to your needs. Plus, with TAFNEX™ you can add a premium forged carbon look, giving your drone a stylish appearance

that stands out. Opting for TAFNEX™ not only enhances your drone’s aesthetics but also significantly boosts its efficiency and safety.

Explore the possibilities and discover how TAFNEX™ can elevate your drone experience to new heights!

TAFNEX™ is a cutting-edge thermoplastic carbon fiber material that is both easily recyclable and lightweight.

Its outstanding versatility in processing allows you to manufacture a wide variety of drone components, each perfectly tailored to your needs. Plus, with TAFNEX™ you can add a premium forged carbon look, giving your drone a stylish appearance that stands out. Opting for TAFNEX™ not only enhances your drone’s aesthetics but also significantly boosts its efficiency and safety.

Explore the possibilities and discover how TAFNEX™ can elevate your drone experience to new heights!

TAFNEX™ is a cutting-edge thermoplastic carbon fiber material that is both easily recyclable and lightweight. Its outstanding versatility in processing allows you to manufacture a wide variety of drone components, each perfectly tailored to your needs. Plus, with TAFNEX™ you can add a premium forged carbon look, giving your drone a stylish appearance that stands out. Opting for TAFNEX™ not only enhances your drone’s aesthetics but also significantly boosts its efficiency and safety.

Explore the possibilities and discover how TAFNEX™ can elevate your drone experience to new heights!

Full-scale drone demonstator

• features three TAFNEX™ components

• first showcased at JEC World 2024

Full-scale drone demonstator

• features three TAFNEX™ components

• first showcased at JEC World 2024

Full-scale drone demonstator

• features three TAFNEX™ components

• first showcased at JEC World 2024

Full-scale drone demonstator

• features three TAFNEX™ components

• first showcased at JEC World 2024

Full-scale drone demonstator

• features three

TAFNEX™ components

• first showcased at JEC World 2024

↓ Learn more about the drone parts below ↓

«Streamlined performance»

«Streamlined performance»

«Streamlined performance»

«Streamlined performance»

«Streamlined performance»

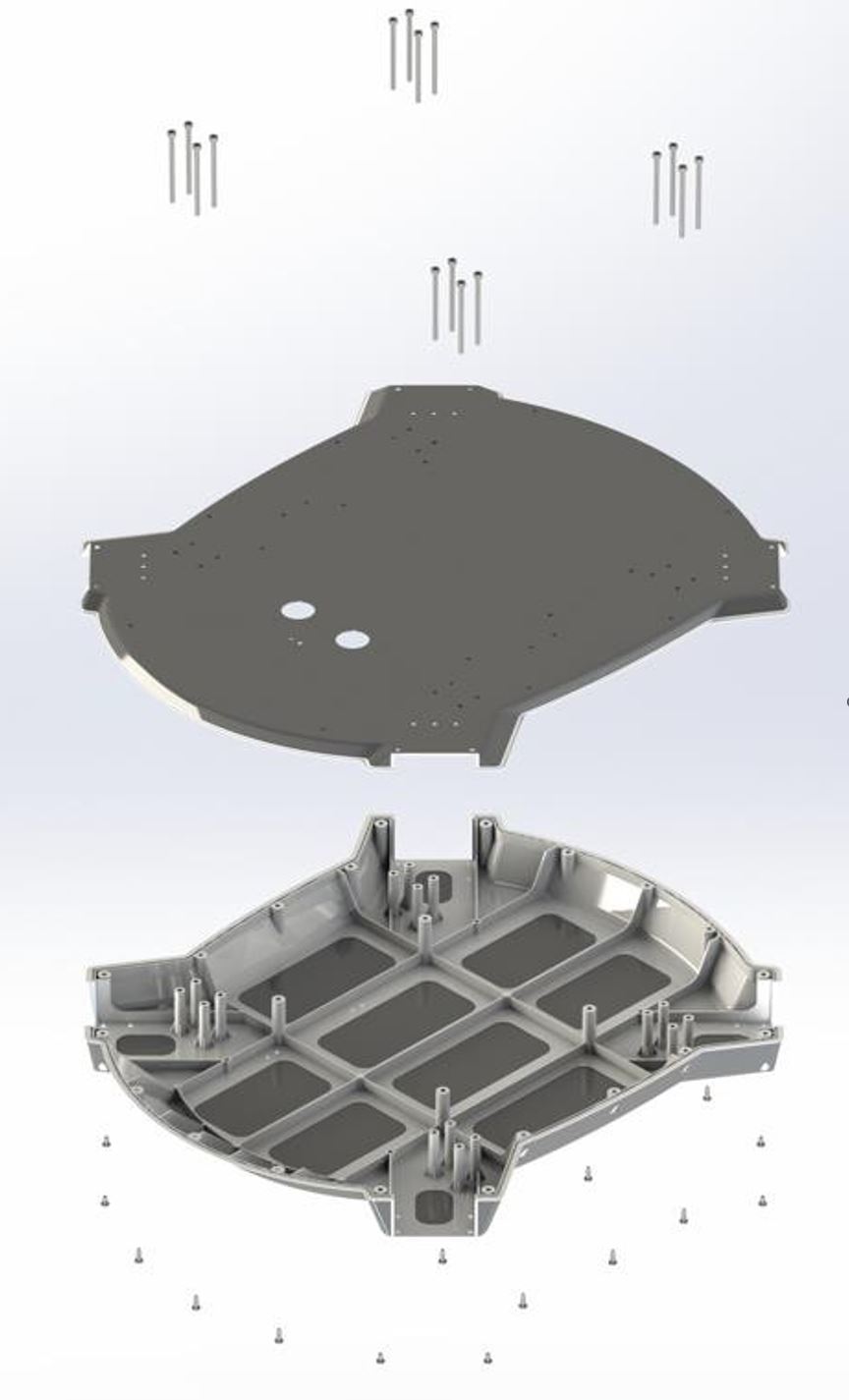

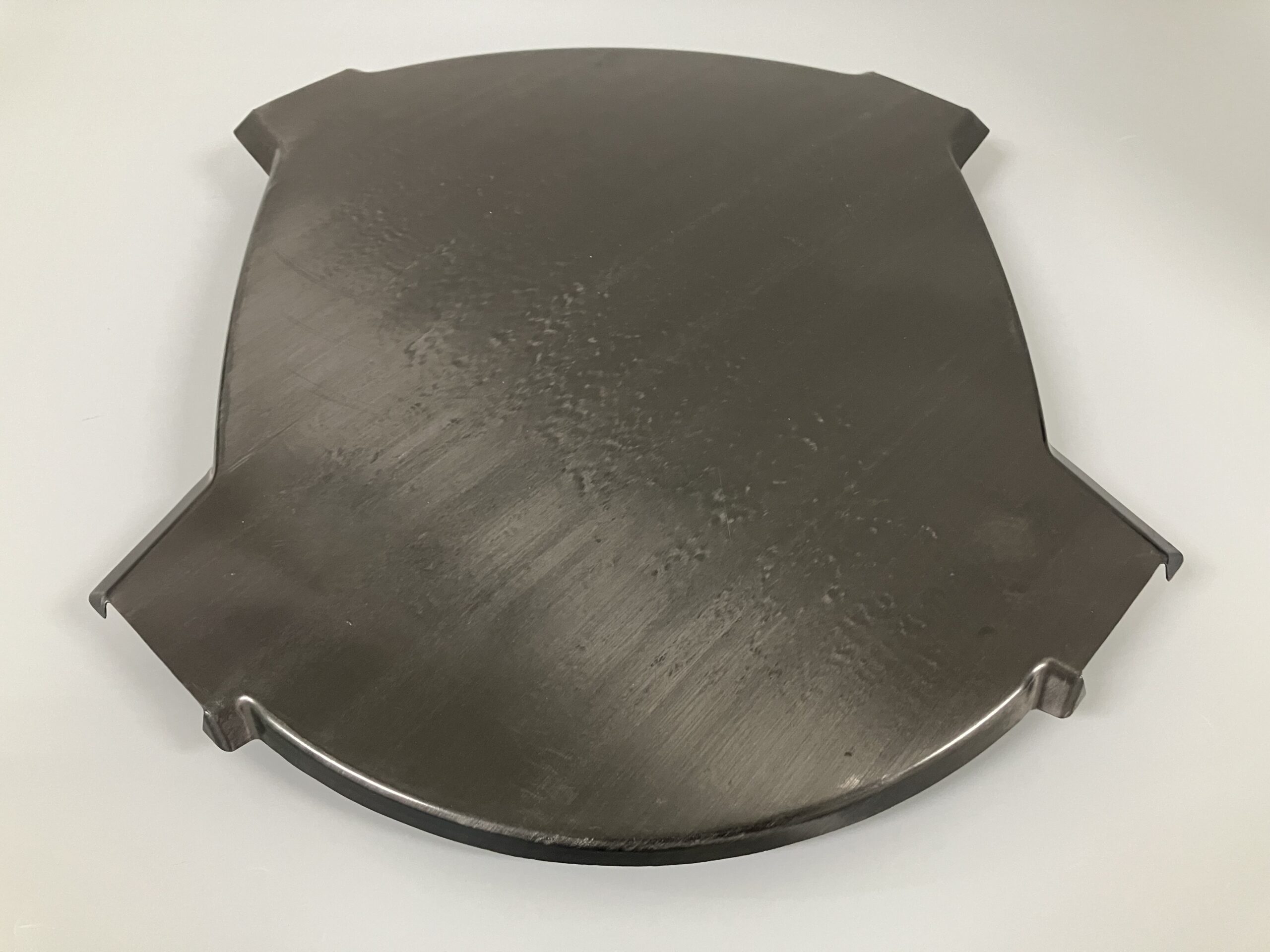

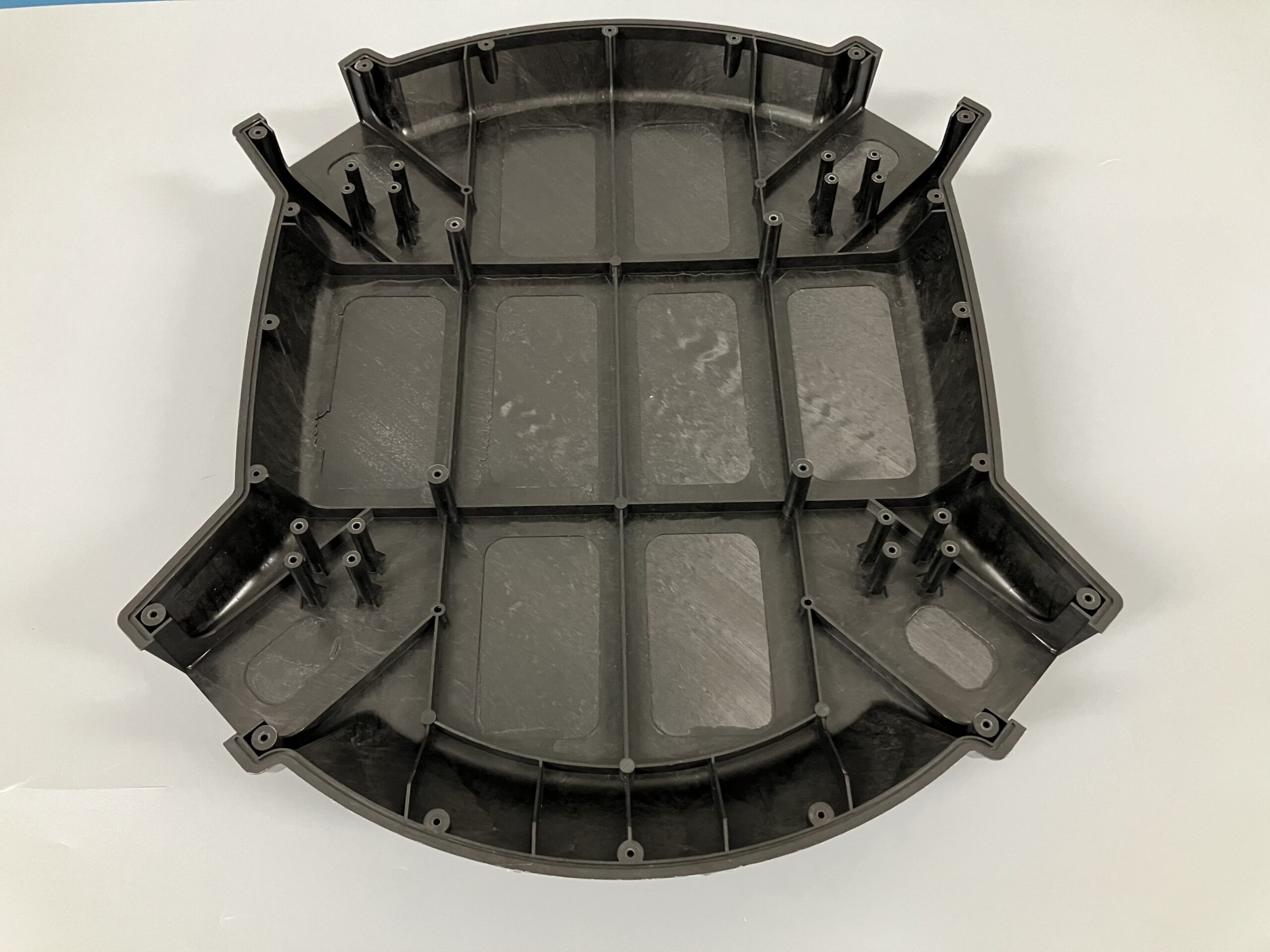

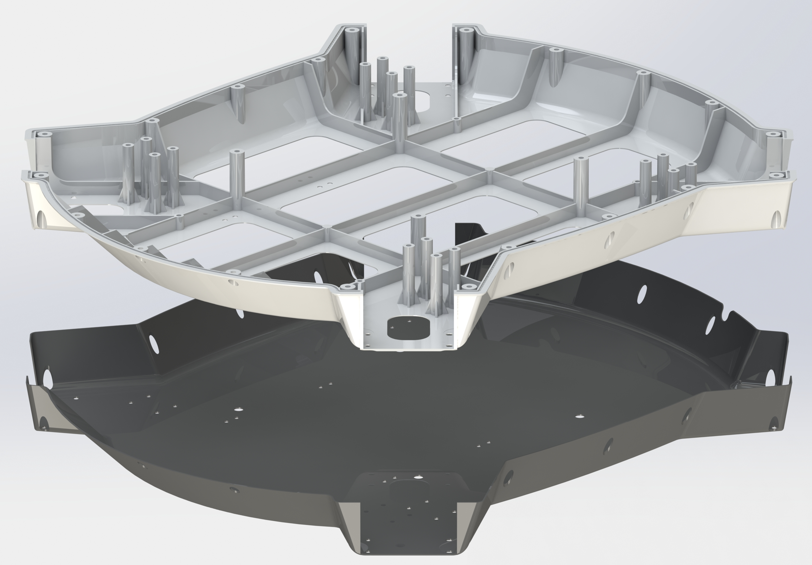

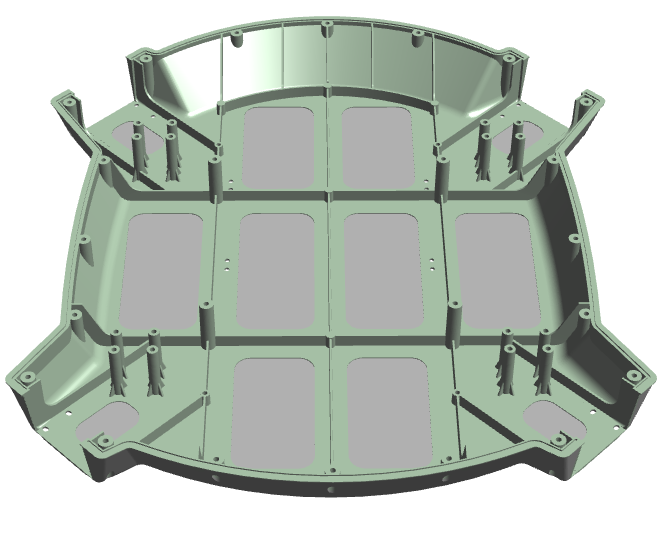

TAFNEX™ Monocoque frame

TAF-NEX™ Monocoque frame

Mono-coque frame

TAFNEX™ Monocoque frame

TAFNEX™ material: Structural sheet

Additional material: PP-GF pellets

Manufacturing process: Injection molding

Status: Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP-GF pellets

Manufacturing process:

Injection molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP-GF pellets

Manufacturing process: Injection molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP-GF pellets

Manufacturing process:

Injection molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP-GF pellets

Manufacturing process:

Injection molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

Gallery:

«Eco-light innovation»

«Eco-light innovation»

«Eco-light innovation»

«Eco-light innovation»

«Eco-light innovation»

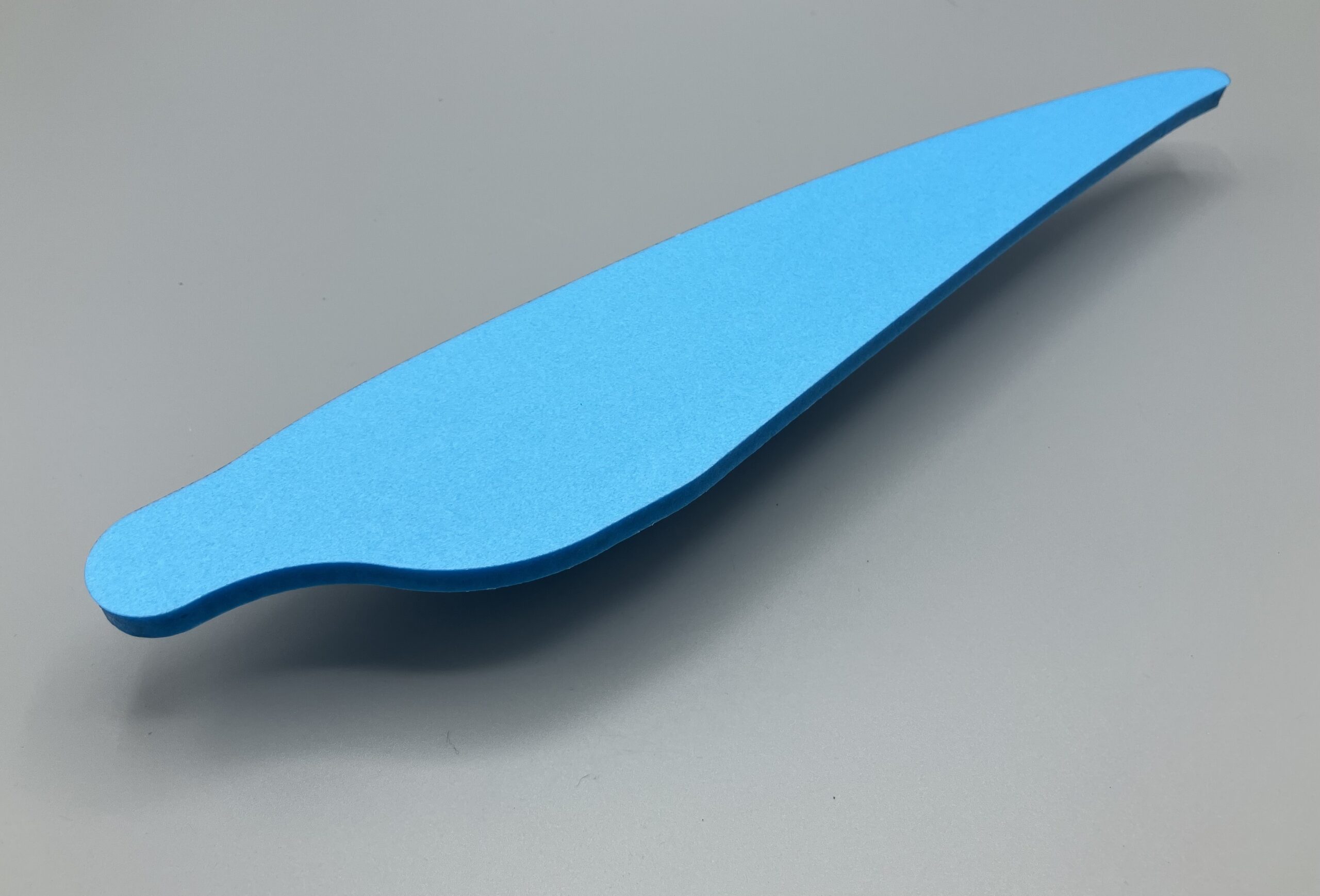

TAFNEX™

Drone arm

Drone arm

Drone arm

TAFNEX™ Drone arm

TAFNEX™ materials: Structural & Design sheet

Additional material: -

Manufacturing process: Compression molding

Status: Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

TAFNEX™ materials:

Structural & Design sheet

Additional material:

None

Manufacturing process: Compression molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

TAFNEX™ materials:

Structural & Design sheet

Additional material:

None

Manufacturing process: Compression molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

TAFNEX™ materials:

Structural & Design sheet

Additional material:

None

Manufacturing process:

Compression molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

TAFNEX™ materials:

Structural & Design sheet

Additional material:

None

Manufacturing process:

Compression molding

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Very low number of individual parts

«Fly in style»

«Fly in style»

«Fly in style»

«Fly in style»

Let's take a ride

TAFNEX™

Drone cover

Drone cover

Drone Cover

TAFNEX™

Drone cover

TAFNEX™ material: Design sheet

Additional material: -

Manufacturing process: Thermoforming

Status: Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Premium forged carbon look

+ High design freedom

TAFNEX™ material:

Design sheet

Additional material:

None

Manufacturing process: Thermoforming

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Premium forged carbon look

+ High design freedom

TAFNEX™ material:

Design sheet

Additional material:

None

Manufacturing process: Thermoforming

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Premium forged

carbon look

+ High design freedom

TAFNEX™ material:

Design sheet

Additional material:

None

Manufacturing process:

Thermoforming

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Premium forged carbon look

+ High design freedom

TAFNEX™ material:

Design sheet

Additional material:

None

Manufacturing process: Thermoforming

Status:

Under development

Benefits:

+ Lightweight

+ Easily recyclable

+ Premium forged carbon look

+ High design freedom

«Silent efficiency»

«Silent efficiency»

«Silent efficiency»

«Silent efficiency»

«Silent efficiency»

TAFNEX™

Drone blade

Drone blade

Drone blade

TAFNEX™

Drone blade

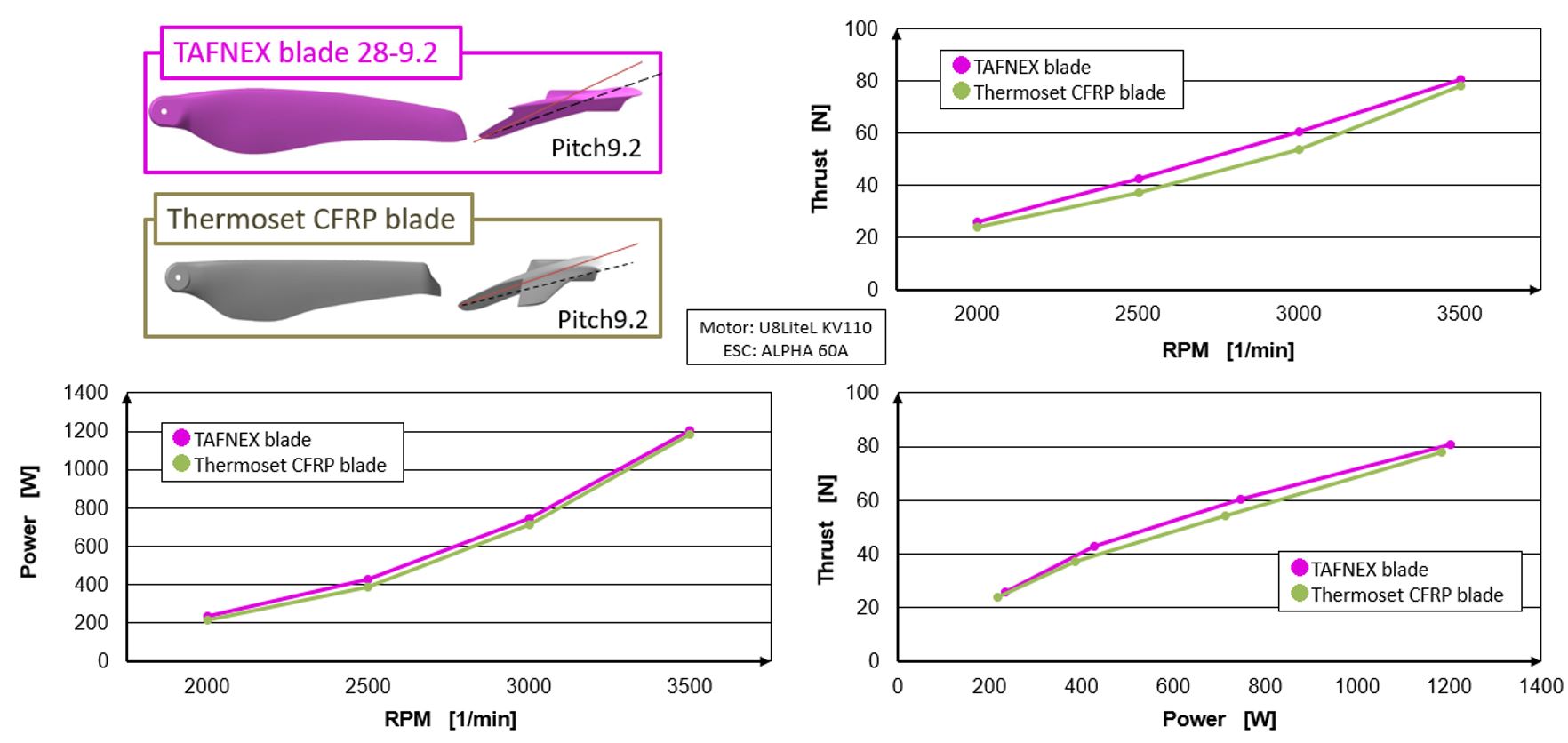

TAFNEX™ material: Structural sheet

Additional material: PP core

Manufacturing process: Thermoforming

Status: Commercialized (Japan)

Benefits:

+ Lightweight

+ Easily recyclable

+ Increasing the drone's cruising range

+ Improving the drone's safety

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP foam

Manufacturing process: Thermoforming

Status:

Commercialized (Japan)

Benefits:

+ Lightweight

+ Easily recyclable

+ Increasing the drone's cruising range

+ Improving the drone's safety

+ Low noise

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP foam

Manufacturing process: Thermoforming

Status:

Commercialized (Japan)

Benefits:

+ Lightweight

+ Easily recyclable

+ Increasing the drone's cruising range

+ Improving the drone's safety

+ Low noise

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP foam

Manufacturing process:

Thermoforming

Status:

Commercialized (Japan)

Benefits:

+ Lightweight

+ Easily recyclable

+ Increasing the drone's cruising range

+ Improving the drone's safety

+ Low noise

Gallery:

TAFNEX™ material:

Structural sheet

Additional material:

PP foam

Manufacturing process: Thermoforming

Status:

Commercialized (Japan)

Benefits:

+ Lightweight

+ Easily recyclable

+ Increasing the drone's cruising range

+ Improving the drone's safety

+ Low noise

Gallery:

↓ Learn more about the benefits below ↓

↓ Learn more about the benefits below ↓

↓ Learn more about the benefits below ↓

↓ Learn more about the benefits below ↓

↓Learn about the benefits below ↓

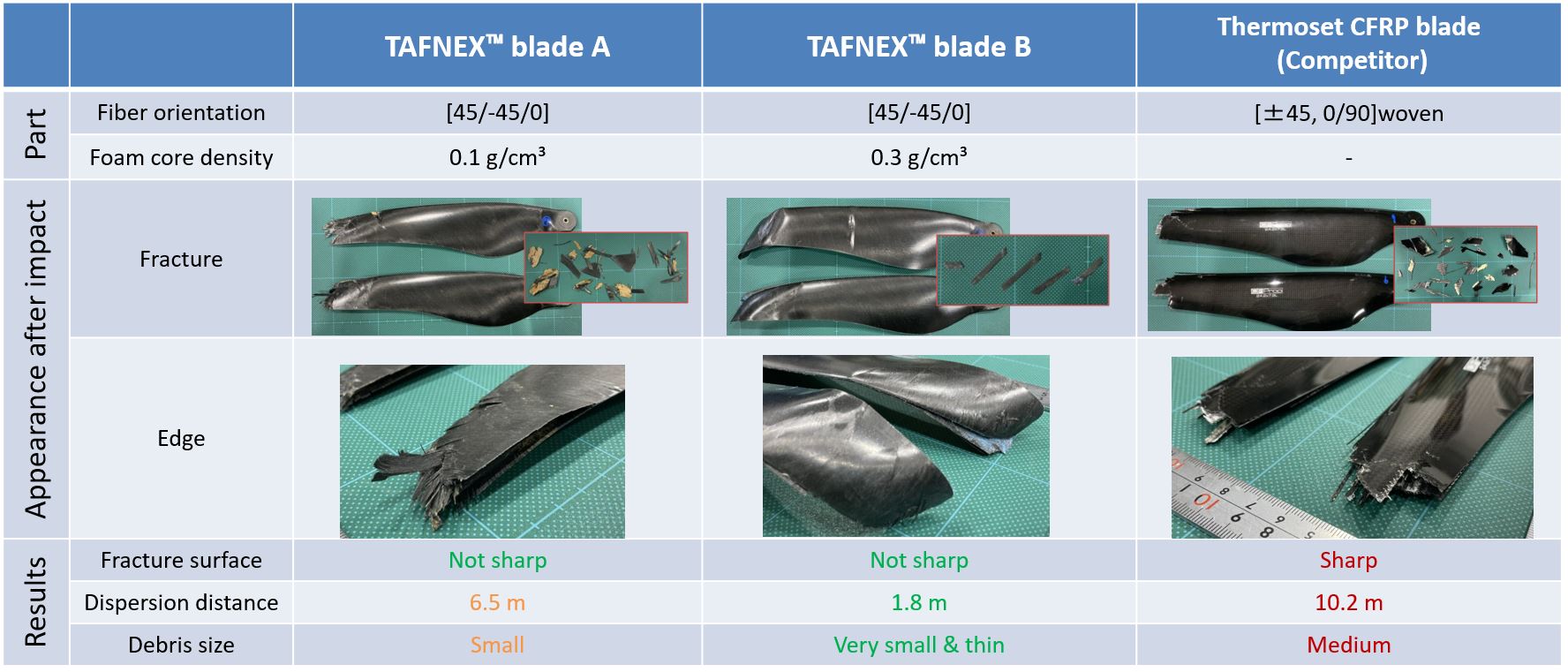

Improved collision safety

«through ductile failure behavior»

TAFNEX™ Drone blades, made entirely from thermoplastic materials, respond to crashes with plastic deformations rather than brittle failure. This results in very small debris that disperses over a minimal area. Additionally, the fracture surfaces are not sharp-edged, making these blades significantly safer for people nearby in the event of an

accident compared to thermoset drone blades.

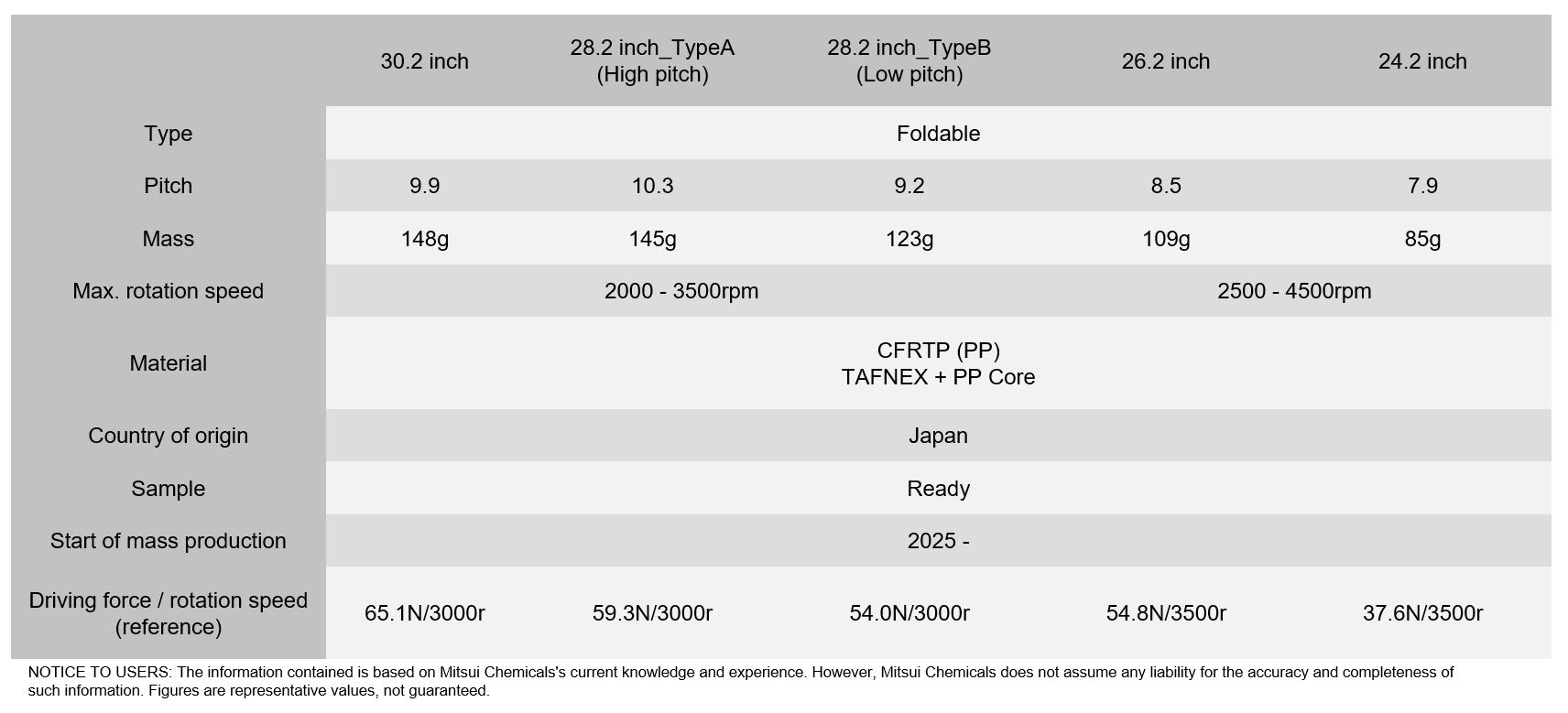

Designs & sizes

«currently available products»

The TAFNEX™ Drone blade portfolio currently includes five products in four different sizes, ranging from 24.2 inches to 30.2 inches. These blades are fully developed and market-ready. Additionally, it is possible to design and produce custom TAFNEX™ Drone blades tailored to specific requirements.

↓ See the blades in action below ↓

TAFNEX™ Drone demonstrator in action

TAFNEX™ Drone demonstrator in action

TAFNEX™ Drone demonstrator in action

Check out the video to see how the drone was brought to life and watch it soar into the sky

Check out the video to see how the drone was brought to life and watch it soar into the sky

Check out the video to see how the drone was brought to life and watch it soar into the sky

Check out the video to see how the drone was brought to life and watch it soar into the sky

Our support portfolio

...

Material support

+ Material development

+ Sample material

+ Customized material solutions

+ Material data

...

Engineering & production

+ Design

+ Engineering

+ Material testing

+ Component testing

+ Tooling

+ Prototyping

...

Simulation

+ Component simulation

+ System simulation

+ Optimization