Thermoplastic tubes are able to accommodate secondary processing. The tubes are possible to reshape. Additionally it is possible to combine the tube in a back injection molding process to integrate new functions and designs on the tube. Compared to thermoset tubes, thermoplastic based tubes have lower vibration and lower sudden breaking down risk.

Benefits of thermoplastic matrix

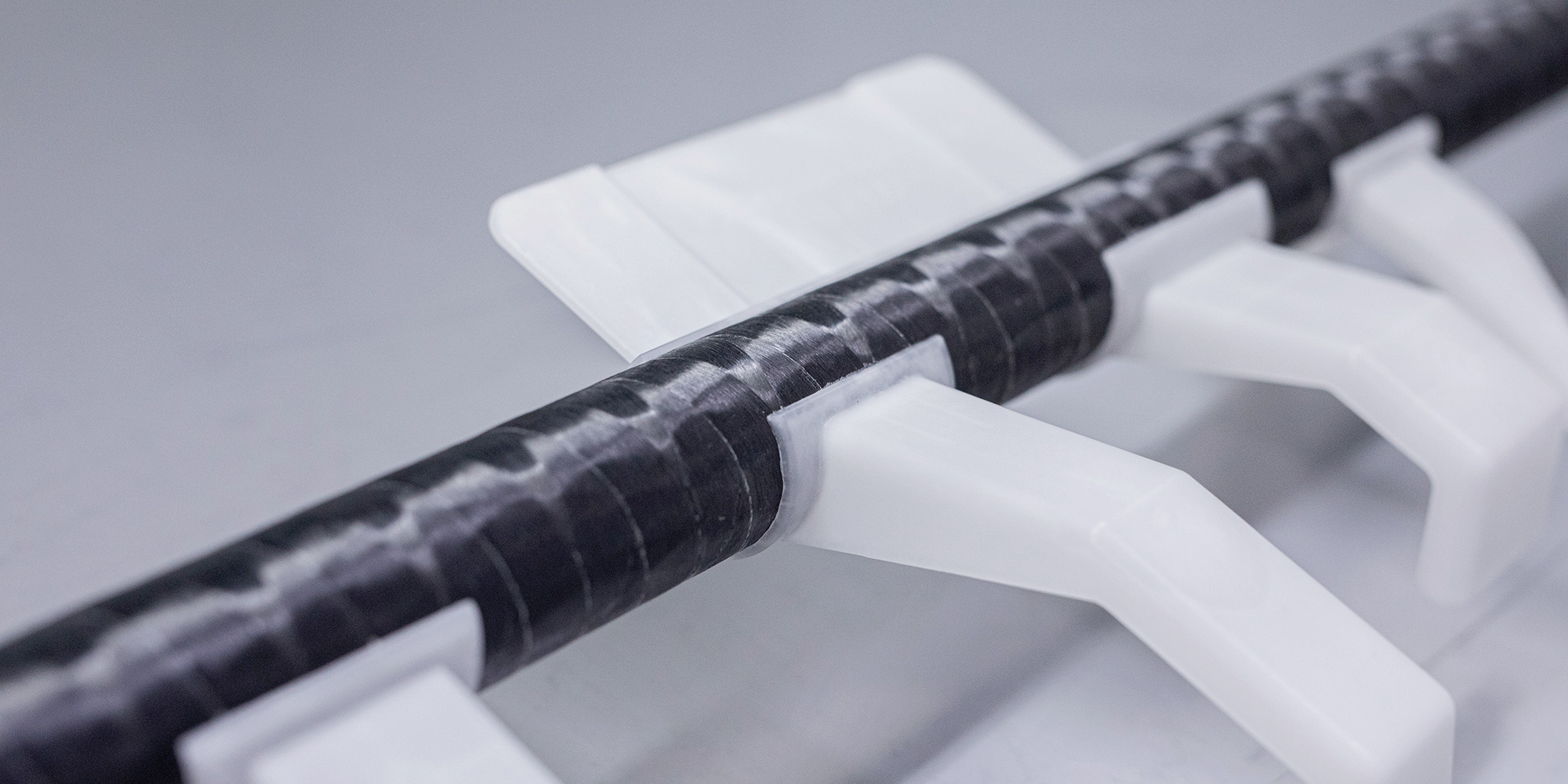

Overmolding of tubes

Tube bending

Related Cases

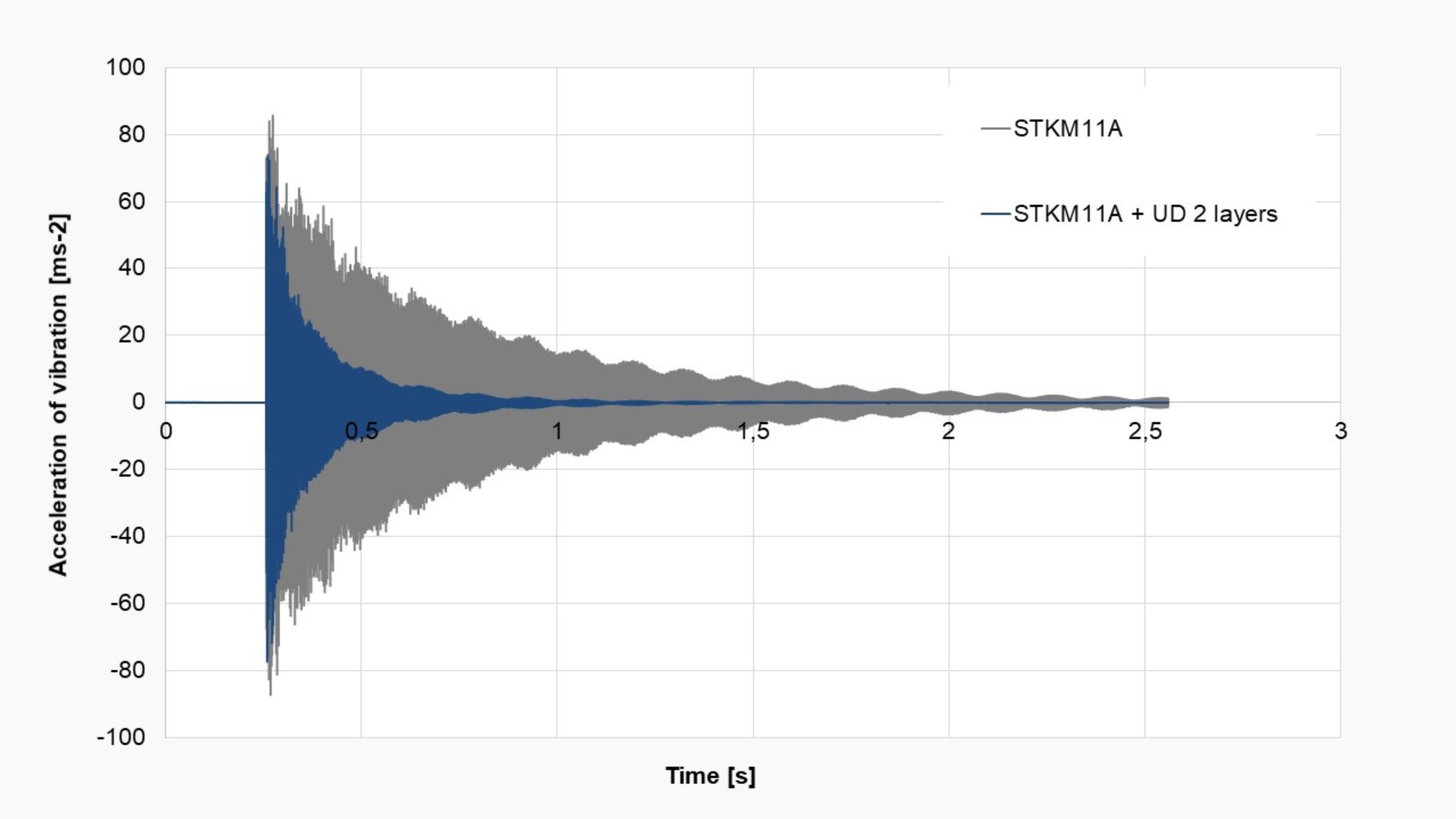

TAFNEX™ CF-PP UD as local reinforcement and for vibration reduction in pipe applications

Vibration reduction in pipe applications by using local reinforcements

Functionalization of thermoplastic profiles

Together with our partners ANYBRID GmbH, INOMETA GmbH and the Institute for Lightweight Construction and Plastics Technology at the Technical University of Dresden, we have rethought the functionalization of high-performance…