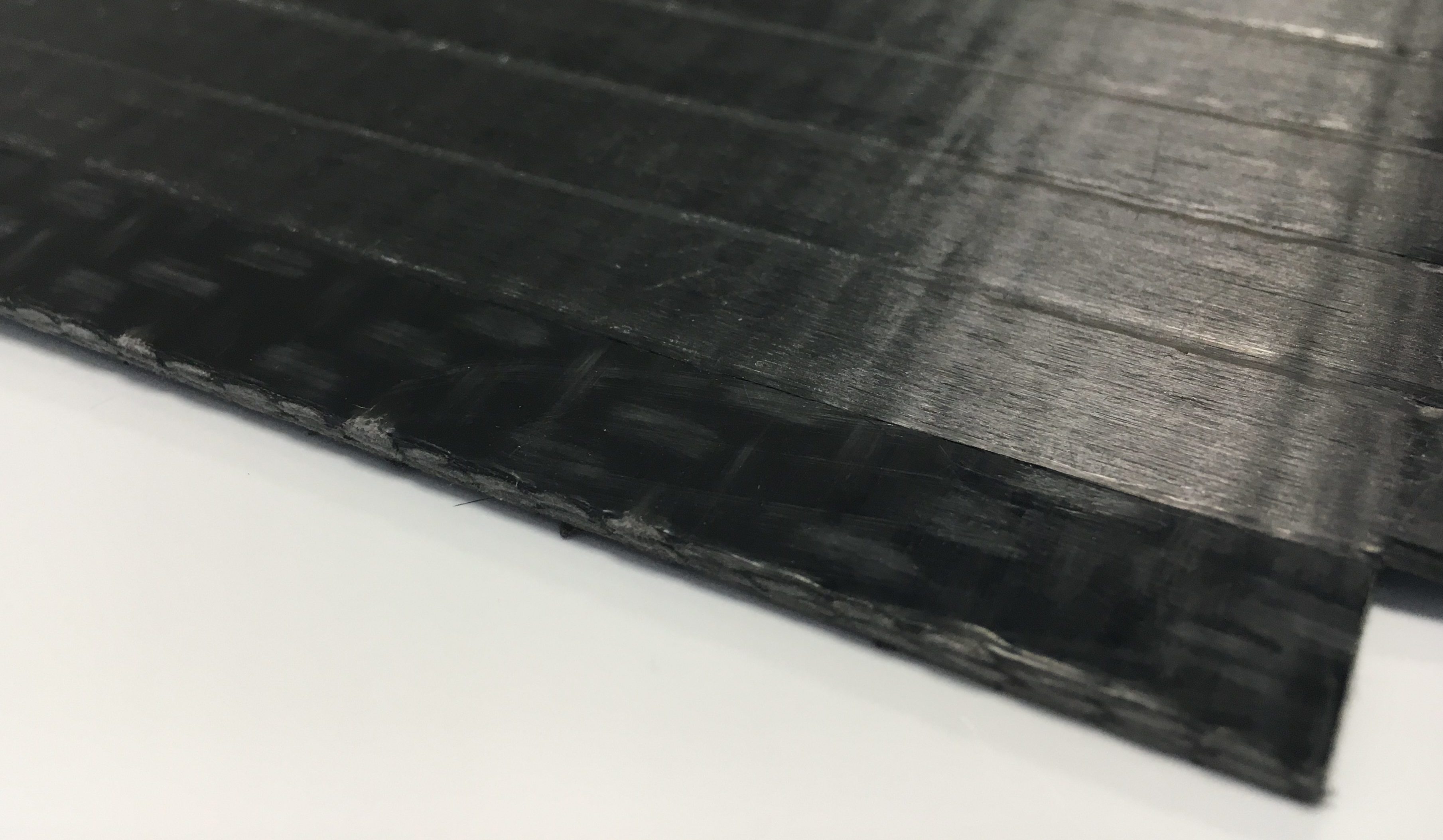

Local reinforcement of organosheets

Local reinforcement of organosheets with TAFNEX™ CF-PP UD Tape improves the stiffness and the mechanical properties.

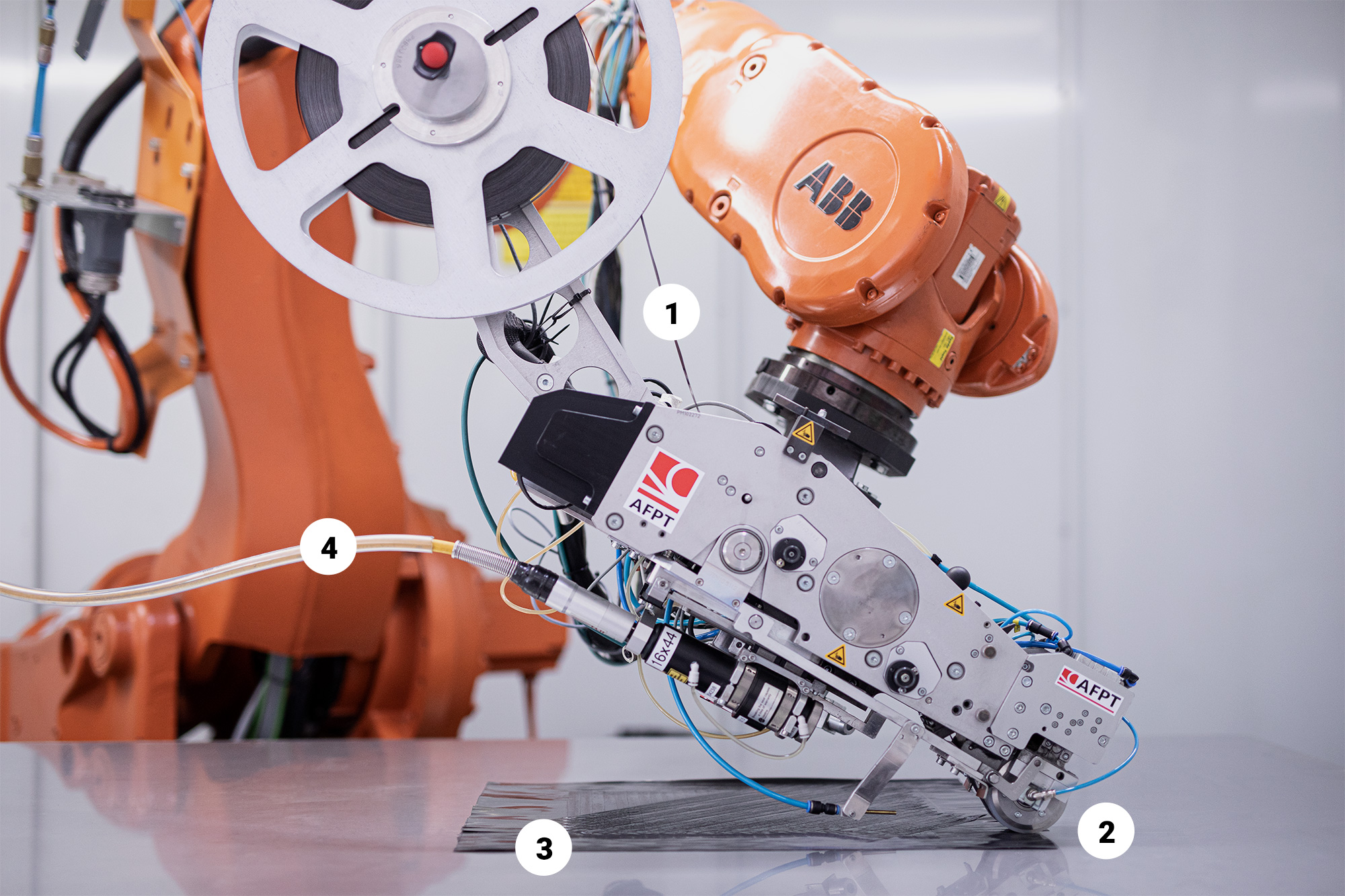

Automated tape placement or winding is an advanced method to produce composite parts. Especially by using laser-assisted technology, it is possible to produce high-strength and high-stiffness parts with a low structural weight. The UD tape is heated locally by laser radiation to the melting temperature and placed under pressure on the geometry (tube or sheet). This method allows that each ply can be placed with different angles to best carry the required loads.

All relevant process parameters such as temperature, tape tension, pressure force, etc. are recorded during the process and can be used for quality control. The in-situ consolidation process does not require any downstream production steps (such as autoclave, press or oven). The tube or sheet is manufactured in one-step and comes out of the machine fully consolidated.

The process can be combined with other processes. Due to the high flexibility of the process, either local components can be reinforced or "tailored blanks" can be produced, which are then processed into the component in further steps.

Legend:

1) Incoming Tape

2) Consolidation Roller

3) Consolidated Tape

4) Heat Source

Individual placement of TAFNEX™ CF-PP UD with the AZL Ultra-Fast Consolidator Machine

Local reinforcement of Organosheets using tape placement technology with TAFNEX™ CF-PP UD

Local reinforcement of organosheets with TAFNEX™ CF-PP UD Tape improves the stiffness and the mechanical properties.

Mechanical properties increased by adding TAFNEX™ CF-PP UD afterwards